Indexing & Abstracting

Full Text

Research ArticleDOI Number : 10.36811/ijpsh.2019.110013Article Views : 53Article Downloads : 37

Effect of the Soil Amendments on the Mechanical Harvest of Potato Crop Grown under Centre Pivot Irrigation System

Dr. Ibrahim Naser1*, Emiliano Olbinado1, Fahad Kasimie2 and James Baker2

1Previous Address: Research Dept., TADCO, Tabuk 71421, P O Box 808, Saudi Arabia

2Previous Address: Vegetable Business Unit, TADCO, Tabuk 71421, P O Box 808, Saudi Arabia

*Corresponding Author: Dr. Ibrahim Naser, Wadi Seer, P O Box 143285, Postal Code, 11814, Amman, Jordan, Email: ibsn2003@hotmail.com

Article Information

Aritcle Type: Research Article

Citation: Ibrahim Naser, Emiliano Olbinado, Fahad Kasimie, James Baker. 2019. Effect of the Soil Amendments on the Mechanical Harvest of Potato Crop Grown under Centre Pivot Irrigation System. Int J Plant Sci Hor. 1: 129-149.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2019; Ibrahim Naser

Publication history:

Received date: 25 September, 2019Accepted date: 07 October, 2019

Published date: 09 October, 2019

Abstract

A field trial was conducted at TADCO to evaluate the mechanical harvest of autumn potato crop under different soil amendments: sand, gypsum, cow manure, and granular sulfur. The application of the sand amendment to the soil of the pivot showed easier mechanical and semi-mechanical harvest. The potato yield under the mechanical harvest was less than semi-mechanical harvest by 15.48% at the different soil amendments. More bruises were observed on the potato tubers harvested by mechanical harvest which ranged 9.34-16.33%, while bruises at semi-mechanical harvest ranged 4.28-4.75%. The final yield of stored potato was less than harvested yield by 10.68, 7.78%, 14.85, 11.08 for the sand, gypsum, cow manure, and sulfur amendments respectively. The stored yield of the different treatments was significantly less than the yield of the test harvest by around 24.03-32.24% at J34 and by 29.64 -56.27% at F18 and this was due to harvest method, cleaning out the damaged potato and moisture loss. The results of this trial highlighted the importance of selecting pivots for growing potato to be with less clay and more sand; also, it highlighted the importance of leaving the wheat straw to decompose in the soil instead of burning to improve the soil structure to be suitable for mechanical harvest. The sand amendment was not suitable for TADCO crop production as it is difficult to apply, need more time to execute besides less productivity. Due to one-month delay in planting potato, the average yield of stored potato from the trial pivots reached 20.2 M.T. /Ha which is significantly less than the yield of stored potato from the other pivots at TADCO of the same season with a range of 27-43 M.T. /Ha.

Keywords: Mechanical Harvest; Soil Amendment; Test Harvest; Soil Clods; Potato Yield; Tubers Bruises

Introduction

The potato crop is grown in the northwest of the Kingdom of Saudi Arabia in two main seasons: Spring Season, planted in early February, harvested in June and Autumn Season planted in late July until mid-August and harvested at the beginning of December and continued until the first week of February [1]. Sometimes, potato is planted on early July to be harvested in November, and therefore the crop may be present in the fields throughout the year. Planting potato outside these dates is encountered with low yield and low quality. The potato crop at this area needs a period of 100-130 days to complete the production cycle, and this region is characterized by a climate of warm days and cold nights in spring and autumn.

Modern field crops production under centre pivot irrigation system in the deserts areas under high temperature in summer and cold temperature in winter involved the use of farm machinery for land preparation, crops maintenance through the use of sprayers of pesticides or fertilizers spreaders, use harvesting machinery specially for perennial forage crops like alfalfa where cutting and bailing of the crop is carried out 6-9 times each season. In the case of potato crop production, it involves high trafficking operations including land preparation, ridging, mechanical harvesting and transportation of the crop from the field to the cold stores under variable soil moisture and climatic conditions. For wheat crop, land preparation for several years using heavy machinery created hardpan at a depth of around 30 cm. Straw burning frequently carried out to speed up land preparation before planting potato or corn on August or directed to control high infestations of grasses such as rye-grass, downy brome which were hard to control by herbicides. All of these factors in addition to increased soil salinity affected soil structure and created soil compaction and the presence of soil clods [2]. It is well known fact that when the soil is tilled too dry, it will typically result in large dry hard clods which were difficult to break down. Also, if the soil tilled when it is too much wet it lead to the formation of soil clods. The lack of organic material into the soil due to straw burning before planting was one of the major causes for the formation of soil clods in addition of heavy trafficking [3-5].

Over most of the last decade, TADCO frequently conducted mechanical harvest mainly for harvesting seed potato. However, the company was applying semi-mechanical harvest for potato crop intended for chipping industry, so they rely on manual labors to collect the potato harvest after the diggers raise the tubers on the soil surface. There were limitations on the availability of manual labors for this work besides the rising cost of manual labors, so this type of operation did not satisfy the company future. The objective of this research work was to evaluate the mechanization of potato crop harvest after the application of the soil amendments.

Materials and Methods

Land Preparation & Experimental Layout

Two pivots J34P85 and F18P35, each 50 Ha, were chosen to test the effect of different soil amendments on the potato crop of autumn 2012 season. These pivots were planted with wheat crop in 2012 season after two years of alfalfa. Due to the short period left between wheat crop harvest late June and potato planting, straw burning option was carried out on the two pivots to speed up land preparation. Pre-irrigation of two rounds of irrigation at a speed of 20% with a total amount of 37.6 mm was carried out. The irrigation process was followed by soil cultivation with a chisel plow at a depth of 15-18 cm then broadcast NPK fertilizer 14-38-10 at the rate 280 kg/Ha followed by cross chisel plow at a depth of 30 cm in the opposite direction (45 ° angle). The pivots were left until soil amendments treatments.

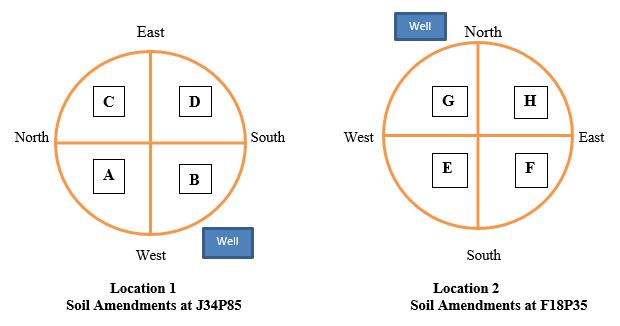

Each pivot was divided into four sections through the arrangement of two crossing roads passing the center of the pivot as shown in Figure 1. The soil amendments treatments were applied at each pivot during the month of August and before planting potato crop. Each soil amendment was applied at the specified rate as shown under each pivot, see Table 1. Another round of 20% irrigation was applied followed by disking for further break of the soil clods and to mix the soil amendments followed by leveling using heavy pipe to settle the soil surface followed by planting potato seeds by the first week of September 2012 using four-row Grimme planter at a raw distance of 90 cm, distance between the seeds in each raw was 29 cm at a rate of 3.1 M.T seeds/Ha. (Three weeks late from the optimum planting date).

Figure 1: Layout of the different soil amendments treatments into the two center pivots trial.

Location 1 at J34P85

A - Sand: Spread by grader up to 10 cm surface layer (12.5 Ha) = 1000 M3/Ha.

B. Control 1: (12.5 Ha), no amendment.

C. Control 2: (12.5 Ha), no amendment.

D. Gypsum: (12.5 Ha), 3 M.T/Ha: Purity 85%, particle size 0-1.5mm, spread by fertilizer spreader.

Date of Planting: September 01, 2012; Variety: Diamant

Location 2 at F18P35

E. Control 3: (12.5 Ha), no amendment.

F. Organic Manure :( 12.5 Ha) = 50 M3/Ha, with the following analysis: pH=8.26, Ec=33.3, %P=0.007, %K=0.04, %Ca=0.15, %Mg= 0.04, %Cl=0.04, %Bicarbonate=0.03, spread by fertilizer spreader.

G. Sulfur Granular: (12.5 Ha): Primstone 1 M.T/Ha: Purity 90%, granules 2-4mm, spread by fertilizer spreader.

H. Control 4: (12.5 Ha), no amendment.

Date of Planting: September 03, 2012; Variety: Markies

|

Table 1: Quantities and cost of the different soil amendments applied into the two center pivots. |

|||||||

|

Amendment Item |

Unit |

Quantity/Ha |

Area (Ha) |

Total Quantity |

Unit Price |

Total value (SR) |

Total Value (USD) |

|

Compost |

M.T |

50 |

12.5 |

625 |

249.4 |

155,875 |

41566.67 |

|

Sulfur |

M.T |

1 |

12.5 |

12.5 |

1,880.0 |

23,500 |

6266.67 |

|

Gypsum |

M.T |

3 |

12.5 |

37.5 |

290.00 |

10,875 |

2900 |

|

Sand |

M3 |

1001 |

12.5 |

12512.5 |

7.8125 |

97,753.9 |

26067.71 |

|

Grand Total for 100 Ha Area |

288003.9 |

76801.04 |

|||||

|

Cost/Ha |

2880.03 |

768.01 |

|||||

Harvesting Equipments

TADCO arranged with a local contractor to execute the mechanical harvest at the trial pivots. The harvesting machinery for the trial pivots included: Grimmey mechanical harvester brought by the contractor, one tractor for the harvester, two tractors with tipping trailers, Miedema cleaning line to clean potato harvest in the field, three Haith trailers for potato transportation to cold stores.

Research personnel were directed to monitor the crop development at both locations and collect data on plant density, average number of tubers/plant, collect leaves samples, conduct test harvest/10 linear meters, take notes on mechanical harvest in the field and follow the harvested crop at the cold stores, collect data on clods size & density and collect tubers samples for quality tests.

Results and Discussion

For the purpose of getting high quality of potato product with acceptable profitability, TADCO applied an integrated crop management system at the various stages of the crop production including field selection, proper land preparation, irrigation and crop nutrition, potato ridging, pest and disease control, foliage removal and tubers skin hardening before harvest in preparation for successful mechanical harvest. Great attention was directed towards the selection of the appropriate pivots [6-7] for growing this crop to overcome the problems of pests, diseases and weeds to maximize productivity and reduce the cost. The pivots were chosen to be as much as possible free from high or low sites, with a loamy to sandy loam soil and are characterized with good permeability and free from stones or solid clay blocks, the salinity of the soil is less than 2 mille-Siemens. Pre-irrigation before the cultivation of the crop was conducted to reduce salinity and to hasten the decomposition of the previous crop residues. A source of good water quality should be available for the required area throughout the growth of the crop, and the land to be free from the contamination with perennial weeds and difficult to control grasses. The potato crop should be planted after two or three years crop rotation and the previous crop should be wheat or barley and avoid planting after alfalfa or onions or potatoes; for fields with hardpan, sub-soil cultivation to a depth of a minimum 40 cm were carried out. Several researchers reported the role of farm machinery trafficking during the growing season for ridging and spraying, and they considered it as an important factor causing soil compaction and the formation of soil clods at the time of harvest which cause bruising on potato tubers [4,5,8]. Success in the mechanical harvest of potato crop involves understanding the different factors affecting it such as weather temperature, soil temperature and tubers temperature, soil moisture content, crop maturity, variety resistance, presence of stones and/or clods, status of harvesting machinery and skills of operators [9-10].

Observations on the performance of potato crop at the different soil amendments

Field measurements on plants density at the different soil amendments treatments of each pivot were carried out on October 14, 2012 (44 days after planting). Results at J34P85 are presented in Tables 2: the mean number of plants per 10 linear meters ranged 3.13 - 3.35 and they were not significantly different. Results at F18P35 shown the number of plants per 10 linear meters at the cow manure was 2.05, and this was significantly less than at other treatments which ranged 3.08 - 3.15, see the statistical analysis. Apparently, it was due to high salinity of the organic manure which affected crop emergence; plants densities of other treatments at F18P35 were slightly less than at J34P85.

|

Table 2 |

|||||||

|

Location/Variety |

Treatments |

Number of plants /10 linear Meter |

Total/40 LM |

Mean/LM |

|||

|

Tower 3 |

Tower 4 |

Tower 5 |

Tower 6 |

||||

|

Diamant Variety at J34P85 |

Sand |

35 |

32 |

34 |

33 |

134 |

3.35 |

|

Control 1 |

34 |

31 |

28 |

32 |

125 |

3.13 |

|

|

Control 2 |

28 |

32 |

33 |

34 |

127 |

3.18 |

|

|

Gypsum |

33 |

35 |

35 |

21 |

134 |

3.35 |

|

|

|

|||||||

|

Markies Variety at F18P35 |

Control 3 |

30 |

29 |

31 |

33 |

123 |

3.08 |

|

Cow Manure |

14 |

25 |

15 |

28 |

82 |

2.05 |

|

|

Sulfur |

30 |

30 |

31 |

32 |

123 |

3.08 |

|

|

Control 4 |

32 |

30 |

31 |

33 |

126 |

3.15 |

|

The following is the statistical analysis on the number of plants/10 linear meter at the two pivots:

- J34P85:

Randomized Complete Block AOV Table for Number of plants/10 linear meters

Source DF SS MS F P

Towers 3 18.750 6.2500

Amend 3 15.250 5.0833 0.28 N.S. 0.8366

Error 9 161.750 17.9722

Total 15 195.750

- F18P35:

Randomized Complete Block AOV Table for Number of plants/10 linear meters

Source DF SS MS F P

Towers 3 60.750 20.250

Amend 3 332.250 110.750 9.52** 0.0037

Error 9 104.750 11.639

Total 15 497.750

Grand Mean 28.375

CV 12.02

Relative Efficiency, RCB 1.10

Means of Number of Plants/10 linear meters for Soil Amendments

Amendments Mean

Control 3 30.750

Cow Manure 20.500

Sulfur 30.750

Control 4 31.500

Observations per Mea 4

Standard Error of a Mean 1.7058

Std Error (Diff of 2 Means) 2.4124

T value for = (30.75 – 20.5)/2.4124 = 4.145*** (DF 9) Between Control 3 and Cow Manure; also between Sulfur and Cow Manure.

T value for = (31.50 – 20.5)/2.4124 = 4.559*** (DF 9) Between Control 4 and Cow Manure.

Effect of the soil amendments on the clod’s formation

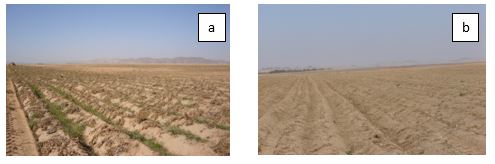

At the time of harvest on the mid of January 2013, we observed the formation of different size clods at the two locations. So, we conducted a survey on the number and size of the clods at the two pivots. As per the field observations, the clods were formed at the different locations of the pivot’s dependent on the soil structure and the effect of the diggers during harvest as shown in Figure 2a and 2b.

Figure 2: Soil clods and potato tubers appeared after the digger operation.

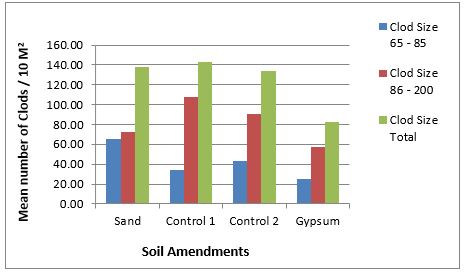

The mean number of the different size clods (mean of four replicates) at the different soil amendment treatments at J34P85 is shown in Table 3 and Figure 3.

|

Table 3 |

||||

|

Treatment |

Mean Number of Clods / 10 M2 |

Total |

Mean Number of Clods/10 M2 |

|

|

Clod Size 65 – 85 mm |

Clod Size 86 – 200 mm |

|||

|

(A) Sand |

65.00 |

72.75 |

137.75 |

68.87 |

|

(B) Control 1 |

34.50 |

108.00 |

142.50 |

71.25 |

|

(C) Control 2 |

43.50 |

90.25 |

133.75 |

66.87 |

|

(D) Gypsum |

25.00 |

57.50 |

82.50 |

41.25 |

Relatively more small size clods were found at the sand treatment and control 2 than in the control 1 and gypsum treatment which they produced 34.5, 25 clods/10 M2 respectively; more large size clods were found in control 1 and control 2 with less numbers in the sand treatment and gypsum treatment as they produced 72.75, 57.5 clods/10 M2 respectively. The number of small clods, large clods and total number of clods/10 M2 at the gypsum treatment was the lowest in comparison with the control areas and sand treatment an indication of slight improvement on the soil structure; the results also showed less large clods at the sand treated area than the control areas.

Figure 3: Column graph representation for the mean number of different size clods/10 M2 on the different soil amendment treatments at the time of harvest of J34P85.

Statistical analysis using Statistix 10 software had shown no significance difference between the amendments in the mean number of formed clods/10 M2 as shown in the following results:

Completely Randomized AOV for of number of clods/10 M2 at J34P85

Source DF SS MS F P

Amendments 3 4697.1 1565.71 1.09 N.S. 0.3687

Error 28 40142.8 1433.67

Total 31 44839.0

Grand Mean 62.063 CV 61.01

Component of variance for between groups 16.5048

Effective cell size 8.0

Means of number of clods / 10 M2 for Soil Amendments

Amendments Mean

(A) Sand 68.875

(B) Control 1 71.250

(C) Control 2 66.875

(D) Gypsum 41.250

Observations per Mean 8

Standard Error of a Mean 13.387

Std Error (Diff of 2 Means) 18.932

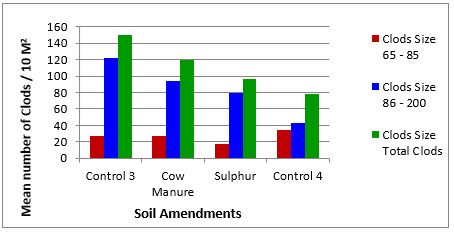

The mean number of the different size clods (mean of four replicates) at the different soil amendment treatments at F18P35 is shown in Table 4 and Figure 4.

|

Table 4 |

||||

|

Treatment |

Mean Number of Clods / 10 M2 |

Total |

Mean Number of Clods/10 M2 |

|

|

Clod Size 65 – 85 mm |

Clod Size 86 – 200 mm |

|||

|

(E) Control 3 |

27.25 |

122.50 |

149.75 |

74.87 |

|

(F) Cow Manure |

26.75 |

93.5 |

120.25 |

60.12 |

|

(G) Sulfur, granular |

17.0 |

79.25 |

96.25 |

48.12 |

|

(H) Control 4 |

34.75 |

43.50 |

78.25 |

39.12 |

Figure 4: Column graph representation for the mean number of different size clods/10 M2 on the different soil amendment treatments at the time of harvest of F18P35.

Relatively more small size clods were found at the control 4 area than control 3, cow manure and sulfur treatments as they produced 27.25, 26.75, 17.0 clods/10 M2 respectively; more large size clods were found at the control 3 and cow manure followed by the sulfur treatment and control 4 with 79.25, 43.5 clods/10 M2 respectively. The total number of clods was high on all treatments in comparison with control 4 with less number of clods which reached 39.1 clods/10 M2 due to less clay and more sand content in this area in comparison to other areas, and this was in favor of easier mechanical harvest. The results showed less large clods at the sulfur and cow manure treated areas than the control 3 area.

Statistical analysis using Statistix 10 software had shown no significance difference between the amendments in the mean number of formed clods/10 M2 as shown in the following results:

Completely Randomized AOV for number of clods/10 M2 at F18P35

Source DF SS MS F P

Amendments 3 6057.8 2019.28 1.03 N.S. 0.3957

Error 28 55058.6 1966.38

Total 31 61116.5

Grand Mean 55.281 CV 80.22

Component of variance for between groups 6.61272

Effective cell size 8.0

Means of number of clods /10 M2 for Soil Amendments

Amendments Mean

(E) Control 3 74.875

(F) Organic Manure 60.125

(G) Sulfur 48.125

(H) Control 4 39.125

Observations per Mean 8

Standard Error of a Mean 15.678

Std Error (Diff of 2 Means) 22.172

Effect of the soil amendments on the mechanical harvest of potato crop

Mechanical harvest of the potato crop was carried out through the application of two methods: semi-mechanical and mechanical harvest.

A- Semi-mechanical harvest: It was carried out through the following operation steps [9-10]:

- Removal of the matured crop tops two weeks before harvest starts to allow for the hardness of tubers skin to facilitate safe harvest and handling of the crop. The tops were desiccated either by chemical spray of Reglone or the potato foliage was killed by the frost during January month. The dry foliage was removed mechanically by chopping machine, see Figure 5. One round of light irrigation was carried out 24 hours before harvest to facilitate digger operation.

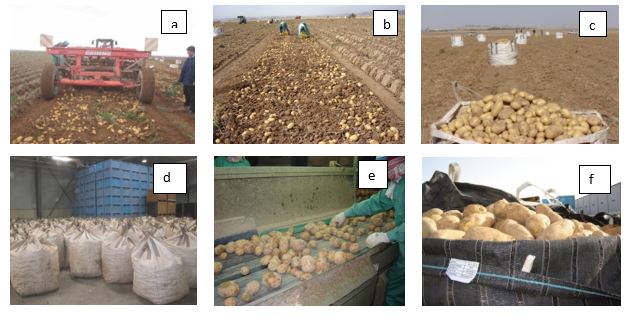

- Digging the ridges around 9:00 AM during winter months and expose the potato tubers to the soil surface for few hours to allow the moisture on the tubers skin to dry out before it was collected manually by the labors then transferred into jumbo bags where it was delivered within few hours after filling to the cold stores and before noon time, see Figure 6a-6d.

- Harvested potato tubers kept in jumbo bags was cleaned, graded then stored in a ventilated cold room at 15o C with relative humidity 95% for 7-14 days dependent on the curing status and the purpose of storage, see Figure 6e-6f.

Figure 5: Potato foliage was killed by frost on January 12, 2012 (5a), and the potato foliage was cleaned before the harvest operation (5b).

- Arrange the potato jumbo bags to either dispatched to the customer or arrange for storage by lowering the temperature 1o C every two days until they reach the required storage temperature for the product: 10 -12o C for French fries, 8-10o C for potato chips. The potato crop was managed successfully with this harvest method, and the product was clean from clods and the potato tubers were with minimum bruises.

Figure 6: Semi mechanical potato harvest steps: (6a) Potato digger exposing the tubers to the soil surface, (6b) collection of potato tubers by the labors, (6c) relatively sound and clean potato tubers collected into the jumbo bags, (6d) potato jumbo bags were delivered to the cold stores by the truks, (6e) potato tubers were graded and packed into jumbo bags before storage, (6f) potato jumbo bags were dispatched to the chips factory after curing.

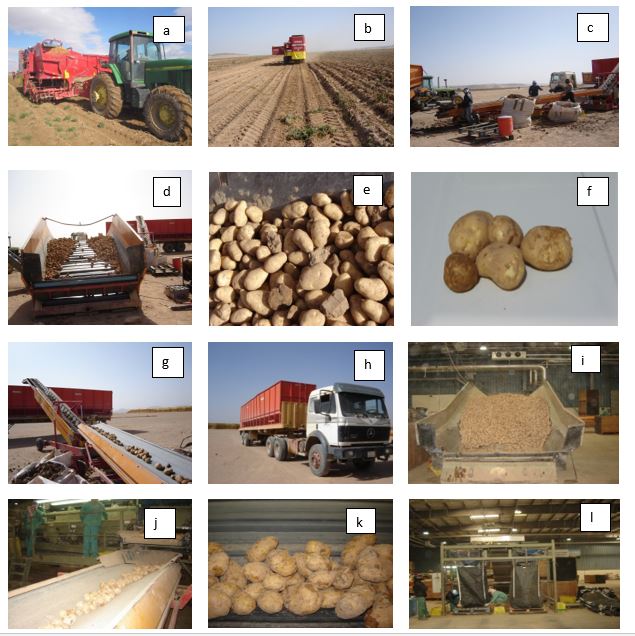

B- Mechanical harvest [9-13]: Operation and production managers arranged for optimum mechanical harvest operation steps starting from land preparation, mechanical planting, crop maintenance, removal of potato haulm after crop maturity, monitoring the tubers temperature, soil moisture at the various steps of harvest and monitor tubers conditions until storage, adjustment of chains and shakers to minimize clods and simultaneously minimize tubers skinning, minimize the number of drops, height of drops to less than 15 cm and lower the distance between machines and piles in agreement with the procedures recommended by different potato researchers [9-13]. It was arranged to conduct full mechanical harvest of five hectares at each quarter of each pivot using Grimme mechanical harvester through the following operation steps:

- Removal of the matured crop tops similar to the previous method Figure 5.

- Four harvest steps were carried out by Grimme harvester in one operation: digging the ridges,

removal of soil & rubbish, separation of stones and clods from the tubers, delivery of the tubers to the cleaning line Figure 7a - 7b.

- Cleaning the harvested tubers on the Miedema cleaning line in the field Figure 7c-7g

- Deliver potato tubers by the mechanical elevator to the loading trucks Figure 7g.

- Transport the potato bulk to the cold stores by Haith trailers Figure 7h.

- Cleaning and grading the tubers and either pack into jumbo bags or deliver the potato bulk to the cold rooms for curing and storage on ventilated cold rooms at 15o C with relative humidity 95% for 7 -14 days Figure 7i -7l.

- Arrange the potato jumbo bags to either dispatched to the customer or arrange for bulk storage by lowering the temperature 1o C every two days until they reach the required storage temperature for the product: 10-12o C for French fries, 8-10o C for potato chips, 4o C for table potato, 2-3o C for potato seeds. The potato tubers harvested by the mechanical harvest were with acceptable quality until before storage.

Figure 7: Mechanical harvest of potato crop by Grimme harvester (7a,7b), Miedema cleaning line (7c), delivered potato tubers from the harvester (6d), received potato tubers with hard clods (6e), bruised potato tubers on the Miedema cleaning line (6f), delivery of pre-cleaned tubers into the trailer (g), transportation of bulk potato into trailer to the cold stores (6h). delivery of bulk potato into the grading line at the cold stores (6i), cleaning and grading potato at the grading line (7j), further bruising potato tubers at the grading line (7k), pack potato tubers into jumbo bags before storage or dispatch to the customer after curing (7l).

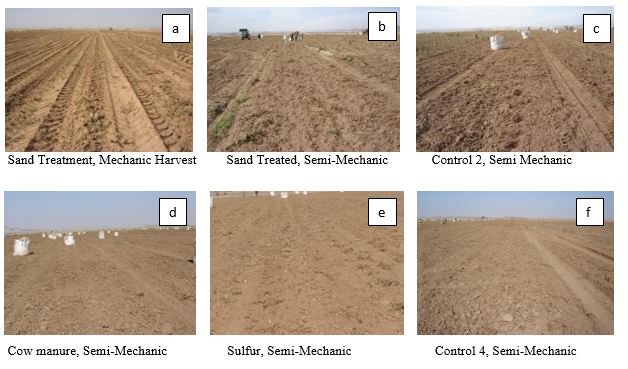

C- Physical Status of the pivots quarters during harvest:

Sand treated quarter: Observations at J34P85 shown the soil structure is fragile with less clods and easy to disintegrate under the influence of the Grimme harvester, so it was suitable for the mechanical harvester to operate, but patches of poor mixed sand caused stuck-up to the harvester, see Figure 8a. The sand needs better mixing or more cultivation to facilitate easy mechanical harvest. Semi-mechanical harvest at this quarter was easy for the digger operation with the appearance of soft and hard clods on some areas, see Figure 8b; other areas no clods were appeared. Potato tubers collected by the labors were sound with little bruises on few tubers.

Control areas C1 and C2 quarters: Under the influence of the digger, hard and soft clods ranged from small to medium size appeared at the soil surface of J34P85 with sound and excellent appearance of potato tubers. The soil surface appeared as homogenous after the manual tubers collection, and the soil surface was mixed with soft and small clods, see Figure 8c. gypsum treated quarter appeared with soil structure similar to the control quarters.

Figure 8: Physical Status of the treated quarters at J34P85 and F18P35 pivots during mechanical and semi-mechanical harvest of potato crop.

Cow manure treated quarter: Observations at F18P35 shown more clods, soft and hard of different size, see Figure 8d; potato tubers were sound and looking good, but they were of less size than at J34P85 due to delay in maturity. Cow manure treated quarter showed more clods, soft and hard of different size; potato tubers were sound and looking good, but they were of less size than at J34P85 due to delay in maturity. The soil after manual tubers collection appeared with non-homogenous soil structure.

Sulfur treated quarter: Observations at this quarter shown harder clods of medium and large size and the soil after manual tubers collection appeared as non-homogenous, see Figure 8e. A small area appeared with large clods near the service road due to irrigation nozzles leakage.

Control areas C3 and C4 quarters: Control 4 quarter was with better soil structure and appeared as homogenous after manual tubers collection due to its sandy texture, see Figure 8f; and control 3 showed more clods of different size and the soil surface appeared as non-homogenous after harvest.

Effect of the soil amendments and mechanical harvest on the productivity and quality of autumn potato

A- Test Harvest of Diamant variety at J34P85: Test harvest was conducted at each treated quarter to determine the potential yield of the potato crop under the soil amendments and climatic conditions. One week before the start of mechanical harvest on the 10th of January 2013 of this pivot, research personnel conducted test harvest of 10 linear meters samples at towers 3,4.5,6. Samples were collected into separate bags, label them and send them to the lab. The samples were processed for: total sample weight, tubers numbers and weight of four sizes: < 50 mm, 50-55 mm, 55-75 mm, and above 75 mm; also chips quality tests were conducted for %dry matter and %reduced sugar. Replicated data on the yield kg/10 linear meter is represented in Table 5. The data kg/linear meter was multiplied by the factor 11111.11 to get the results into M.T./Ha (90 cm raw spacing) The yield at the sand treatment reached 33.72 M.T which was the highest followed by control 2 with 33.09 M.T./Ha then control 1 with around 32 M.T./Ha. and then gypsum treatment with 30.26 M.T./Ha.

|

Table 5 |

|||||||

|

Treatments |

Replicates (Yield Kg/10 linear Meter) |

Total Kg/40 LM |

Mean Kg/LM |

Yield M.T/Ha |

|||

|

Tower 3 |

Tower 4 |

Tower 5 |

Tower 6 |

||||

|

Sand |

30.5 |

32.20 |

26.70 |

32.00 |

121.40 |

3.035 |

33.72 |

|

Control 1 |

27.6 |

32.70 |

24.00 |

30.90 |

115.20 |

2.880 |

31.99 |

|

Control 2 |

32.8 |

20.80 |

20.30 |

36.20 |

119.10 |

2.978 |

33.09 |

|

Gypsum |

30.30 |

30.10 |

22.70 |

25.80 |

108.90 |

2.723 |

30.26 |

Statistical analysis using Statistics 10 software had shown no significant difference between the different amendments treatments in the yield kg/10 linear meter as shown in the following results.

Completely Randomized AOV for Potato Yield under different soil amendments at J34P85

Source DF SS MS F P

Amend 3 22.432 7.4775 0.38 N.S. 0.7680

Error 12 235.025 19.5854

Total 15 257.458

Grand Mean 29.038 CV 15.24

Component of variance for between groups -3.02698

Effective cell size 4.0

Amendments Mean Yield (Kg/ 10 LM)

Sand 30.350

Control 1 28.800

Control 2 29.775

Gypsum 27.225

Observations per Mea 4

Standard Error of a Mean 2.2128

Std Error (Diff of 2 Means) 3.1293

B- Test Harvest of Markies variety at F18P35

One week before the start of the mechanical harvest on the 14th of January 2013 at this pivot, research personnel conducted test harvest of 10 linear meters samples at tower 3,4.5,6; samples were processed in a similar manner of J34P85. Replicated data on the yield kg/10 linear meter is represented in Table 6. The data Kg/linear meter were multiplied by factor 11111.11 to get the results into M.T./Ha (90 cm raw spacing). More yield was obtained at the sulfur treatment which reached 36.24 M.T./Ha followed by control 4 with 31.78 M.T./Ha then cow manure with 29.81 M.T./Ha. and then control 3 with 27.54 M.T./Ha.

|

Table 6 |

|||||||

|

Treatments |

Replicates (Yield Kg/10 linear Meter) |

Total Kg/40 LM |

Mean Kg/LM |

Yield M.T/Ha |

|||

|

Tower 3 |

Tower 4 |

Tower 5 |

Tower 6 |

||||

|

Control 3 |

26.6 |

24.00 |

25.75 |

22.81 |

99.16 |

2.479 |

27.54 |

|

Manure |

25.05 |

21.15 |

23.00 |

38.11 |

107.31 |

2.683 |

29.81 |

|

Sulfur |

30.15 |

29.31 |

39.30 |

31.70 |

130.48 |

3.262 |

36.24 |

|

Control 4 |

30.85 |

32.95 |

27.20 |

23.4 |

114.40 |

2.860 |

31.78 |

Statistical analysis using Statistics 10 software had shown no significant difference between the different amendments treatments in the yield kg/10 linear meter as shown in the following results.

Completely Randomized AOV for Potato Yield at F18P35

Source DF SS MS F P

Amend 3 132.506 44.1687 1.76 N.S. 0.2077

Error 12 300.721 25.0601

Total 15 433.227

Grand Mean 28.196 CV 17.75

Component of variance for between groups 4.77715

Effective cell size 4.0

Amendments Mean Yield (Kg/ 10 LM)

Control 3 24.790

Manure 26.828

Sulfur 32.615

Control 4 28.550

Observations per Mean 4

Standard Error of a Mean 2.5030

Std Error (Diff of 2 Means) 3.5398

C- Effect of the soil amendment on the quality of potato tubers

Potato tubers samples of Diamant variety were collected from the test harvest of J34P85 treatments and analyzed in the laboratory. The results shown all samples of J34P85 were with acceptable level of %dry matter and % reducing sugar for chipping processing as shown in Table 7. Another potato tubers samples of Markies variety were collected from the test harvest of F18P35 treatments and analyzed in the laboratory. The results shown most of the samples of F18P35 were with acceptable level of %dry matter and % reducing sugar for chipping processing except cow manure treatment was with %dry matter slightly below 19%.

|

Table 7 |

|||

|

Pivot |

Treatment |

%Dry Matter |

%Reduced Sugar |

|

J34P85 |

Sand |

19.60 |

0.27 |

|

Control 1 |

20.60 |

0.15 |

|

|

Control 2 |

20.00 |

0.09 |

|

|

Gypsum |

20.00 |

0.23 |

|

|

F18P35 |

Control 3 |

20.80 |

0.03 |

|

Cow Manure |

18.60 |

0.06 |

|

|

Sulfur |

19.60 |

0.01 |

|

|

Control 4 |

20.00 |

0.05 |

|

|

Acceptable Level |

> 19 |

< 0.4 |

|

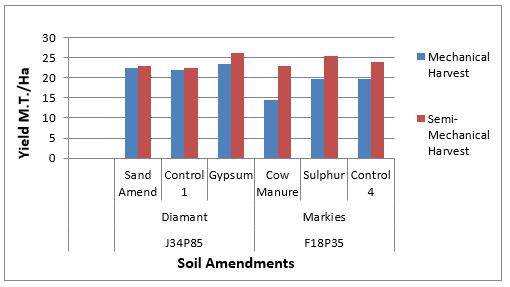

D- Yield of potato crop under the mechanical harvest

As per the plan of the field trial, five hectares were harvested from each quarter treatment at both of the two pivots using Grimmi harvester, and the rest of each quarter (7.5 Ha) was harvested by the Grimme digger. Data on control 2 and control 3 were mixed between the two types of harvest and not correct, so it was excluded from the comparison as we still had one control at each pivot. Productivity of each treatment is presented in Table 8 and Figure 9, we observed the following:

- Due to one month delay in planting the trial pivots as extra time was needed for the field preparations of the soil amendments, the average yield of potato crop at both of the two pivots was low in comparison to other pivots planted earlier at the company site which ranged 27-43 M.T./Ha as per the data shown in Table 9: Cold stores records for the stored potato from J34P85 was 1021.104 M.T with an average yield 20.42 M.T/Ha; and from F18P35, the stored potato was 1000.2 with an average yield 20.00 M.T//Ha. So the average yield of the trial pivots was 20.2 M.T/ha which is significantly less than other pivots at TADCO of the same season.

- Mean productivity at the mechanical harvest was 20.324 M. T which was less than the semi-mechanical harvest by 15.48% which reached 24.046 M.T./Ha.

- Yield of Diamant variety at the gypsum treatment of J34P85 reached 23.5 M.T./Ha which is slightly higher than the sand treatment and control 1 with 22.51, 21.89 M.T./Ha respectively.

|

Table 8 |

||||||||

|

Location |

Variety |

Treatment |

Mechanical Harvest |

Semi-Mechanical Harvest |

||||

|

Area (Ha.) |

Harvested Quantity (M.T.) |

Yield M.T./Ha |

Area (Ha.) |

Harvested Quantity (M.T.) |

Yield M.T./Ha |

|||

|

J34P85 |

Diamant |

Sand Amend |

5 |

112.540 |

22.51 |

7.5 |

173.120 |

23.08 |

|

Control 1 |

5 |

109.450 |

21.89 |

7.5 |

169.000 |

22.53 |

||

|

Gypsum |

5 |

117.740 |

23.5 |

7.5 |

196.50 |

26.22 |

||

|

F18P35 |

Markies |

Cow Manure |

5 |

72.20 |

14.44 |

7.5 |

171.92 |

22.92 |

|

Sulfur |

5 |

98.88 |

19.78 |

7.5 |

190.98 |

25.46 |

||

|

|

|

Control 4 |

5 |

98.92 |

19.79 |

7.5 |

180.56 |

24.07 |

|

Total |

30 |

609.73 |

|

45 |

1082.08 |

|

||

|

Mean |

20.324 |

|

|

24.046 |

|

|||

Figure 9: Effect of soil amendments and mechanical harvest on the productivity of two potato varieties in the autumn of 2012.

- Yield of Markies variety at the sulfur treatment of F18P35 reached 19.78 M.T./Ha which was higher yield than cow manure treatment with 14.44 M.T./Ha.

- Productivity at the sand treatment was almost similar to control 1 at J35P85, but it allowed the mechanical harvester to operate easier than at other locations, so field harvest was faster than the semi-manual harvest.

- Productivity of the mechanical harvest at F18P35 was significantly less than the productivity at J34P85; drop in productivity at this pivot was due to more soil compaction. Productivity at the cow manure treatment was the lowest among all treatments due to high salinity of cow manure fertilizer and it caused delay in crop maturity.

|

Table 9 |

|||||||

|

Location |

Variety |

Area (Ha.) |

Date of Planting |

Harvested Quantity (M.T.) |

Harvested Yield (M.T./Ha.) |

Stored Quantity (M.T.) |

Final Yield (M.T./Ha.) |

|

F08P15 |

Diamant |

40 |

16/7/2012 |

1320.92 |

33.02 |

1154.76 |

28.86 |

|

F02P03 |

Diamant |

50 |

17/7/2012 |

1257.82 |

31.44 |

1118.98 |

27.97 |

|

J09P52 |

Diamant |

50 |

19/7/2012 |

2519.98 |

50.40 |

2170.20 |

43.40 |

|

J16P34 |

Hermies |

50 |

25/7/2012 |

1598.06 |

31.76 |

1366.37 |

27.32 |

|

J28P04 |

Patadco |

50 |

26/7/2012 |

1515.72 |

30.314 |

1366.40 |

27.32 |

|

J40P03 |

Markies |

40 |

2/8/2012 |

1594.65 |

39.86 |

1290.91 |

32.27 |

E- Effect on the quality of potato harvest: Inspections on the potato harvest of J34P85 and F18P35 before grading and storage were carried out at the cold stores for tuber size and defects on the tubers. Summary results of the inspection on five potato samples collected from each harvest type at J34P85 are shown in Table 10. Results showed the majority of the tubers size was within the acceptable size for chipping and it reached 68.13. 73.03% at the semi-mechanical and mechanical harvest respectively. Results showed the bruises damages caused by the mechanical harvest reached 16.33% which is significantly higher than semi-mechanical harvest which reached 4.75%; also, the total defects caused by the mechanical harvest reached 25.26% which is higher than semi-mechanical harvest which reached 14.92%.

|

Table 10: Summary of the inspection on potato tubers samples of Diamant variety collected from the two types of mechanical harvest of J34P85 (mean of five replicates). |

||||||||||

|

Harvest Type |

Weight of Five samples |

%Tuber Size |

%Defects & Damages |

|||||||

|

(Kg) |

50-55 mm |

55-75 mm |

>75 mm |

Mech. Damage |

Bruises |

Dust & Stones |

Others* |

Total Defects |

||

|

Semi-Mechanical |

502.5 |

3.13 |

68.13 |

28.72 |

1 |

4.75 |

0.05 |

8.72 |

14.92 |

|

|

Mechanical |

530.01 |

3.45 |

73.03 |

23.55 |

2.06 |

16.33 |

0.43 |

6.44 |

25.26 |

|

Others*:Cracks,Decay,Under Size, Insect Damage, Greening, Misshape, Mothers, Hollow Heart.

Summary results for the inspection on four potato samples collected from F18P35 from each harvest type are shown in Table 11. Results showed that the majority of the tubers size were within the acceptable size for chipping and it reached 70.47, 72.35% at the semi-mechanical and mechanical harvest respectively. Results showed the bruises damages caused by the mechanical harvest reached 9.34% which is higher than semi-mechanical harvest which reached 4.28%; also, the total defects caused by the mechanical harvest reached 21.46% which is slightly higher than semi-mechanical harvest which reached 18.62%.

|

Table 11: Summary of the inspection on potato tubers samples of Markies variety collected from the two types of mechanical harvest of F18P35 (mean of five replicates). |

||||||||||

|

Weight of Four samples |

%Tuber Size |

%Defects & Damages |

||||||||

|

(Kg) |

50-55 mm |

55-75 mm |

>75 mm |

Mech. Damage |

Bruises |

Dust & Stones |

Others* |

Total Defects |

||

|

Semi-Mechanical |

354.5 |

2.31 |

70.47 |

27.2 |

1.48 |

4.28 |

0.29 |

9.58 |

18.62 |

|

|

Mechanical |

532.18 |

2.56 |

72.35 |

28.84 |

1.7 |

9.34 |

0.34 |

10.06 |

21.46 |

|

Others*:Cracks,Decay,Under Size,Insect Damage, Greening, Misshape,Mothers, Hollow Heart.

F- Effect on final yield: By the end of harvest, we get the data on the yield of stored potato for each treatment of each pivot. The final yield of stored potato for each treatment at J34P85 shown more yield was obtained on the gypsum treatment with 23.18 M. T; the stored yield of the sand treatment and control 1 was less with productivity of 20.41 and 19.17 M.T. / Ha respectively. Productivity at F18P35 ranged from 16.63-20.62 M.T. / Ha which was less than the productivity at J34P85. At F18P35, the stored yield of the sulfur treatment was the highest with 20.62 M.T./Ha followed by control 4 with 19.91 M.T./Ha then cow manure with 16.63 M.T./Ha, see Table 12. Estimation of yield loss due to grading at the cold stores after the two types of mechanical harvest showed a drop-in productivity at J34P85 of 7.78, 10.68% at the sand and gypsum treatments respectively; and at F18P35 a drop-in productivity of 11.08, 14.85% at the sulfur and cow manure treatments respectively. The estimation of yield loss due to method of harvest, cleaning out the damaged potato and due to moisture loss in comparison with the test harvest at J34P85 showed a drop-in productivity of a range 24.03-32.24%, and at F18P35 a drop-in productivity a range of 29.64-56.27%. These results were in agreement with the research results for the effect of mechanical harvest on post storage injury on different potato varieties which ranged 14-72% [14], and in agreement of the results for the effect of mechanical harvest injury on potato marketability which reached 60.1% more than manual harvesting [15].

|

Table 12: Comparison of the productivity of two potato varieties (M.T./Ha.) at J34P85 and F18P35 under different soil amendment treatments. |

|||||

|

Treatments |

Harvested Yield (M.T./Ha.) |

Stored Yield (M.T./Ha.) |

%Difference in Productivity |

Test Harvest Yield M.T/Ha. |

%Difference in Productivity |

|

J34P85, variety Diamant |

|||||

|

Sand |

22.85 |

20.41 |

- 10.68 |

33.72 |

- 32.24 |

|

Control 1 |

22.28 |

19.17 |

- 13.96 |

31.99 |

- 30.35 |

|

Gypsum |

25.14 |

23.18 |

- 7.78 |

33.09 |

- 24.03 |

|

F18P35, variety Markies |

|||||

|

Cow Manure |

19.53 |

16.63 |

- 14.85 |

29.31 |

- 33.37 |

|

Sulfur |

23.19 |

20.62 |

- 11.08 |

36.24 |

- 56.27 |

|

Control 4 |

22.36 |

19.91 |

- 10.96 |

31.78 |

- 29.64 |

Summery and Conclusions

- Field observations shown clods of different sizes and numbers were formed at the different locations of the pivots under the effect of the diggers during harvest dependent on the soil structure and soil moisture; clods formation was an indication of poor soil structure, and this occurred due to field trafficking for soil ridging, field spraying during the growing season [4-5]. The process of soil structure improvement occurs over a relatively longer period of time. The total number of clods/10 M2 at the gypsum treatment was the lowest in comparison with the control areas and sand treatment area at J34 an indication of slight improvement on the soil structure.

- The sand treatment facilitated easier mechanical harvest with almost little or no clods left on the soil surface after the mechanical harvester operation. The Semi-mechanical harvest of potato crop was managed successfully with product clean from clods and the potato tubers were with minimum bruises and excellent appearance, and the potato tubers of the mechanical harvest were with acceptable quality until before storage.

- The physical Status of the sand treated quarter was with breakable clods which disintegrated under the effect of Grimme harvester, and the sand treatment was suitable for mechanical harvester to operate, but patches of poor mixed sand caused stuck-up to the harvester as sand needed better mixing or more cultivation to facilitate easier mechanical harvest. Semi-mechanical harvest at the sand quarter was easy for the digger operation with the appearance of soft and hard clods on some areas, but no clods appeared in other areas. Potato tubers collected by the labors were sound with little bruises and excellent appearance.

- Control areas at J34 showed the presence of clods of variable density dependent the soil structure, the soil surface appeared as homogenous after the manual tubers collection;and the gypsum treated quarter appeared with soil structure similar to the control quarters.

- Cow manure treated quarter showed more clods, soft and hard of different size; potato tubers were sound and looking good, but they were of less size than at J34P85 due to delay in maturity; and the soil surface appeared with non-homogenous soil structure after manual tubers collection.

- Sulfur treated quarter showed clods, soft and hard of medium and large size and the soil surface appeared with non-homogenous soil structure after manual tubers collection.

- Control 4 quarter was with better soil structure and appeared as homogenous after manual tubers collection due to its sandy texture, but control 3 showed more clods of different size and the soil surface appeared with non-homogenous soil structure after harvest.

- Test harvest was conducted at each treated quarter of each pivot to determine the potential yield of the potato crop under the soil amendments and climatic conditions. Productivity of the different treatments at J34 was not significantly different and ranged 30.26-33.72 M.T./Ha; and Productivity of the different treatments at F18 was not significantly different and ranged 27.54-36.24 M.T./Ha.

- The lab tests on the harvested potato tubers showed all samples from the different treatments of both pivots were with acceptable level of %dry matter > 19% and % reducing sugar < 0.4% for chipping processing except cow manure treatment was with %dry matter slightly below 19%.

- The mean yield of the mechanical harvest for both pivots were 20.324 M. T which was less than the semi-mechanical harvest yield by 15.48% as it reached 24.046 M.T./Ha. Although productivity at the sand treatment was almost similar to control 1 at J34P85, but it allowed the mechanical harvester to operate easier than at other locations, so mechanical harvest was faster than the semi-mechanical harvest. Productivity of the mechanical harvest at F18P35 was significantly less than the productivity at J34P85; as it dropped due to more soil compaction. Productivity at the cow manure treatment was the lowest among all the treatments due to high salinity of cow manure fertilizer and it caused delay in crop maturity.

- Diamant variety yield at the gypsum treatment reached 23.5 M.T./Ha which is slightly higher than the sand treatment and control 1 with 22.51, 21.89 M.T./Ha respectively. Yield of Markie’s variety at the sulfur treatment produced 19.78 M.T./Ha which was higher than cow manure treatment with 14.44 M.T./Ha and equal to control 4 with 19.79 M.T./Ha.

- Due to one-month delay in planting the trial pivots, the average yield of stored potato from both of the two pivots reached 20.2 M.T./Ha which is significantly low in comparison to the yield of other pivots planted earlier at the company site in autumn 2012 which ranged 27-43 M.T./Ha. So, sand amendment was not suitable for TADCO crop production as it is difficult to apply, need more time to execute besides less productivity.

- Comparison on the quality of potato harvest at the two pivots before grading and storage at J34P85 and F18P35 showed the majority of the Diamant and Markie’s tubers were within the acceptable size for chipping processing.

- The bruises on the tubers of J34P85 harvest caused by the mechanical harvest reached 16.33% and this was significantly higher than the semi-mechanical harvest as it reached 4.75%; also, the total defects caused by the mechanical harvest reached 25.26% which was significantly higher than the semi-mechanical harvest which reached 14.92%. Similar results were obtained at F18P35 as the tubers bruises reached 9.34%, 4.28% for the mechanical harvest, semi-mechanical harvest respectively; also, the total defects reached 21.46%, 18.62% for the mechanical harvest, semi-mechanical harvest respectively.

- The estimation of yield loss due to harvest method, cleaning out the damaged potato and due to moisture loss in comparison with the test harvest at J34P85 showed a drop-in productivity of a range 24.03 -32.24%, and at F18P35 drop in productivity ranged 29.64-56.27% [14-15].

Recommendations

- Select as many as possible pivots with less clay and more sand.

- Deep chisel rip to just below compaction layer to break the compacted layer (soil dry to slightly moist).

- Add gypsum before chiseling.

- Add organic manure 5 M.T./Ha before planting; maintain and manage crops straw in the soil before planting instead of burning.

- Minimize field operations trafficking.

- Proper moisture when land preparation is carried out.

References

1. TADCO. Ref.: https://bit.ly/2AHvILh

2. Voss RE. 2013. A report to TADCO, Summary of Observations, and Suggestions/Recommendations, consultancy visit 1-7.

3. Giesel B, Delanoy L. 2010. Field preparation in relation to soil compaction & formation of clods in the publication entitled: Commercial Potato Production, Manitoba Agriculture, Food and Rural Initiatives. Canada.

4. USDA, Soil compaction symptoms, causes, correction, and prevention. 2008.

5. Mckenzie RH. 2010. Agricultural soil compaction: causes and management. Ref.: https://bit.ly/2oogZ57

6. Haluschak P, Mckenzie K, Panchuk K. 2010. Field selection in the publication entitled: Commercial Potato Production, Manitoba Agriculture, Food and Rural Initiatives, Canada.

7. Hollebrandse, P. Steyn, F. (2004). Soil preparation for potato planting, article prepared for McCain Chips Co. Ref.: https://bit.ly/331imp7

8. Campbell DJ. 1989. A review of the clod problem in potato production. 27: 373-395. Ref.: https://bit.ly/2AJwZBz

9. Lindsay GG. 1985. Mechanization in potato production-Agronomy Society of New Zealand. Ref.: https://bit.ly/2VcVdNT

10. Thornton, M, Bohl, W. Preventing potato bruise damage, University of Idaho, College of Agriculture, Bul. 725. Ref.: https://bit.ly/2AIBAny

11. GRIMME | Best of potato harvesting technology 2011. Ref.: https://bit.ly/2Va4xlK

12. Johnstone, R. 2016. Improve potato quality by minimizing mechanical damage. Ref.: https://bit.ly/2LJsg9i

13. Pavlista AD. 2015. Bruises of potato tubers, Nebraska University. Ref.: https://bit.ly/337ftU1

14. Misener GC, Tai GCC. 1993. Relative resistance of potato varieties to serious mechanical injury. Ref.: https://bit.ly/30J3bzt

15. Misener GC, Mcleod CD, Walsh JR, et al. 1988. Effect of potato harvesting injury on post-storage marketability. Ref.: https://bit.ly/2ncG3vs ijpsh_raft1013