Indexing & Abstracting

Full Text

Review ArticleDOI Number : 10.36811/ojae2019.110002Article Views : 6Article Downloads : 9

An overview on use of desiccant dehumidifiers in modern air-conditioning

Jani DB

Gujarat Technological University, GTU, Ahmedabad, India

*Corresponding Author: Jani DB, Gujarat Technological University, GTU, Ahmedabad, India, Email: dbjani@rediffmail.com

Article Information

Aritcle Type: Review Article

Citation: Jani DB. 2019. An overview on use of desiccant dehumidifiers in modern air-conditioning. Open J Archit Eng. 1: 16-31.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2019; Jani DB

Publication history:

Received date: 20 November, 2019Accepted date: 29 November, 2019

Published date: 02 December, 2019

Abstract

The solid desiccant based dehumidifier used in conjunction with the conventional HVAC combines the dehumidification of solid desiccant system and with the cooling capacity of the conventional air conditioning system. This hybrid cooling system provides thermal comfort to the occupants of the conditioned space. The hybrid systems main appeal lies in the fact that, it consumes much lesser high grade electrical energy as compared to the dedicated standalone traditional air conditioning systems. The electrical energy usage is possible still lower by use of primary energy sources for to supply the thermal energy needed for the desiccant regeneration. For this purpose freely available renewable solar energy or industrial waste heat can also be used for the regeneration heat source. Sometimes it is also possible to provide condenser waste heat for the part of desiccant reactivation heat supply may increase the overall performance of the system. It was also found that this cooling system with use of air to air waste heat recovery wheel performed better than without it in terms of dehumidification as well as cooling performance. The present study report important literature survey on the dehumidification potentials of desiccant integrated hybrid cooling system operating in hot and humid climates.

Keywords: Hybrid air-conditioning; Rotary desiccant dehumidifier; Heat recovery wheel; Regeneration heat; Renewable solar energy; Waste heat

Introduction

Solid desiccant based modern air conditioning system (SDMAC) combines the dehumidifying capability of a solid desiccant integrated dehumidification system judiciously coupled with the cooling capability of traditional cooling system to provide thermal comfort to the occupants of a conditioned space in the residential and commercial buildings. The main benefit of this hybrid system, if properly designed, it requires less electrical power than the conventional vapor compression based HVAC systems. A recent optimization study has indicated that an electrical coefficient of performance is found more than 6 [1] could be attained which quite higher than the traditional air conditioners. The reason behind the same is that the total cooling load handled separately in dehumidifier and sensible cooling coil. Furthermore, it neglects the maintenance of low dew point temperature (usually around 2-4°C) in evaporator coil and well as post re-heating if any. The latent heat load in terms of room moisture is to be removed effectively by the use of rotary dehumidifier while the sensible cooling coil can handled only the sensible cooling load at comparatively much higher temperature (usually around 14-17°C). So, it reduces the much compression work at the same time energy waste in thermal heating for attaining the room supply conditions in case of overcooling. Moreover, the use of air-to-air heat recovery wheel increase the heating in the regeneration side while cooling the process air side resulted to much efficient and economical operation of the system. Furthermore, reactivation energy requirement if can be met with freely available renewable solar energy, electrical energy requirement lowers further to meet the economical feasibility of the hybrid cooling system. Recently, there have been several research works on solid desiccant assisted air conditioning which investigate various related technical and economic performances of the systems and different components like as dehumidifier, heat wheel, sensible cooling coil etc. [1-14]. Earlier, Henning [15] conducted a review on various possible system configurations based on different operating conditions suitable for variable ambient climate for the tropical regions whilst Camargo and Ebinuma [16] developed thermodynamic equations of the system with focus on the hot and humid climatic conditions. To make desiccant assisted hybrid cooling viable the system must be properly designed to achieve the following requirements: (1) to reduce the parasitic energy consumption, (2) to lower the use of regeneration heat, (3) to provide thermal comfort in variable environmental conditions especially during humid ambient. To achieve the above goals, several system configurations were proposed by many investigators in the different part of the world as per the outdoor requirements that are expected to suit specific climatic conditions [15]. Other configurations can be found in [5,7,17]. The standard desiccant cooling cycle mentioned in [15] was recently studied to investigate the system performance for hot and humid tropical climate [18] with mixed results; i.e., a slightly better electrical COP compared with the traditional vapor compression based room air conditioning system but with the indoor thermal comfort conditions of the indoor building spaces were not fully satisfied.

The economical feasibility of desiccant based hybrid cooling largely depends of its dehumidification potential in terms of reactivation energy requirement. The present overview evaluates the dehumidification capability of a desiccant assisted traditional cooling system equipped with an air to air heat recovery wheel. In the previous study [18], the performance of the single stage desiccant assisted cooling reported in the earlier studies [5-8] was evaluated with variable cooling requirement of the conditioned space in hot and humid climate. The findings [15] echo the conclusions presented in [5]. However, no research work has been carried out on the performance analysis of desiccant based hybrid cooling system for typical applications in tropical and subtropical climates where latent cooling load is an important criteria when RSHF reduces below 75%. To develop this desiccant based hybrid cooling system as an alternative to the energy intensive traditional vapor compression system, it is important to assess the dehumidification potential which will help the design of systems for hot and humid tropical regions of the world. Therefore, the current study focuses on dehumidification and cooling characteristics of desiccant integrated modern air conditioning system for an air conditioning the residential and industrial buildings in the hot and humid climate conditions.

Background of the present study

In places typically have hot and humid climates such as near to the sea shore, tropical, green rain forest etc. has air-conditioning systems which are essential for human comfort in-connection to effective humidity control. The challenge for air-conditioning systems in especially extreme weather is to control indoor air quality (IAQ) while meeting the building cooling in term of sensible and latent cooling loads effectively. Countries with hot and humid climates can experience extreme temperature and humidity levels to handle the increased moisture load which make the correct design of air-conditioning systems vital. Improper design of air-conditioning systems often leads to poor indoor air quality issues due to lack of proper ventilation air and severe health problems, thermal comfort detriment and higher energy consumption. CO2 levels in the indoor air often at places like as auditorium, theater, dormitories etc. cannot be diluted enough may affect the human health and productivity of workers in industries. It is well proven that the poor indoor air quality could reduce the performance of office work by 6–9%. Furthermore, airborne pollutants do not escape the occupied air conditioning space and hence affect occupants’ health and productivity to major level which cannot be neglected [54-55].

Conventional vapour compression based traditional VCR refrigeration systems are popular amongst designers, builders and famous among the HVAC engineers. This is because the system is simple, well known among designers and commercially available easily. In this traditional air-conditioning system design, the sensible and latent loads of a particular space are being treated by the same air-handling unit in which the dry bulb temperature (DBT) is the only parameter which can get effectively controlled while humidity is separately handled as a by-product of the temperature control. There is no direct control of the humidity despite very high outdoor humidity levels in typical hot and humid climates. Due to this inherent limitation in the system design, the target dry bulb temperature (DBT) is achieved, but the relative humidity is out of the comfort range i.e. 50-55%. Furthermore, this lack of control of humidity can lead to bacteria population and failed to achieve optimal indoor air quality and thermal comfort via traditional VCR based cooling systems results in greater energy use. Therefore, in conventional vapor compression air conditioning systems, comfort conditions can only be provided when sensible heat ratio (SHR) is greater than 0.76. This value can be significantly less, especially for the hot and humid climatic conditions, and thus optimum comfort conditions cannot be fully achieved by the traditional air conditioning. Due to this condition when sensible heat ratio (SHR) is more than 0.76, the thermal comfort cannot be targeted either. Another drawback of the traditional air conditioner is the evaporation of condensate coming out from the unit into the conditioned space due to overcooling which may result in increased humidity levels in the same cooling space. In desiccant cooling technology, major components of the systems are a rotary desiccant dehumidifier and an evaporative cooler. Low-grade thermal energy such as freely available renewable solar energy and industrial waste heat can be used in these systems to regenerate the desiccant dehumidifier while renewable energy such as solar panels can help drive the fans and water pump. This system can operate on a wide range of sensible humidity ratios because of decoupling of sensible and latent cooling loads by effectively handling them separately. Therefore, desiccant assisted air dehumidification and air conditioning system become popular in coming days for the reduction of air humidity and temperature because of its application of renewable energy sources such as freely available renewable solar energy and industrial waste heat. Evaporative cooling systems are highly efficient cooling technologies for cooling in hot climates conditions. However, in extremely high humidity conditions such as those within the range of 75–89%, many investigators propose an integration of the desiccant dehumidifier and evaporative cooler technologies (also known as desiccant assisted evaporative cooling systems). Earlier investigations also reported that the desiccant assisted evaporative cooling systems in four seasonal countries had saved energy of up to 68% in hot and humid summer seasons. Despite its favourable results so far, the desiccant-enhanced evaporative cooling technology is still under the process of development and more intensive research and contribution need to be investigated for the development of this technology. In this paper, a review of desiccant-based evaporative cooling applications is presented focusing on hot and humid climate regions. In industrial and large-scale applications, solid desiccant dehumidification is the most convenient method for elimination of water vapor from the conditioned space [56-57].

System description

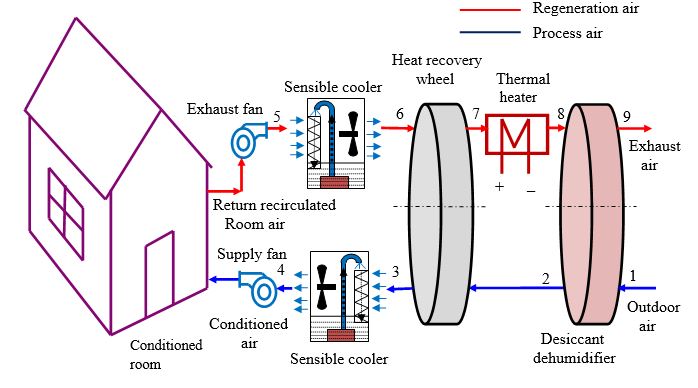

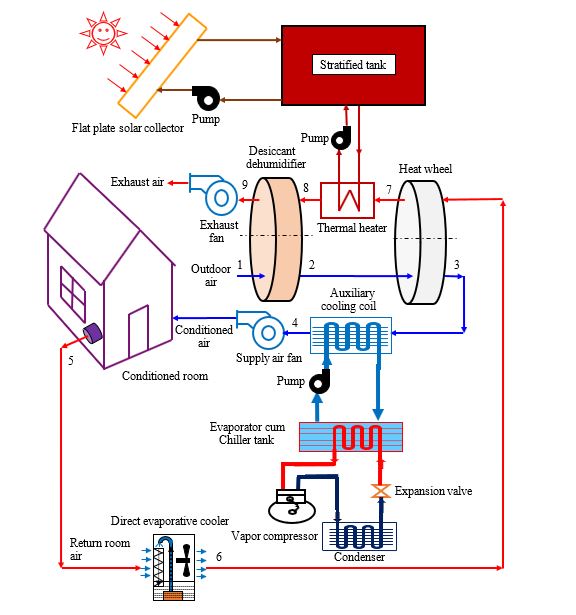

A solid desiccant dehumidification integrated cooling system consists of a desiccant dehumidifier, air to air heat recovery wheel, sensible cooling coil and a regeneration thermal heat source, as shown in Figure. 1 [19]. In case of the ventilation air circulation mode, the fresh ambient air is used for dehumidification. The desiccant wheel significantly dehumidifies the supply process room air but increases its temperature slightly (State point 1-2). The initial cooling of this warm and dry process supply air takes place in the air to air heat recovery wheel (State point 2-3), the humidity of the air remains constant during this process of sensible cooling. Before being supplied to the conditioned room indoor space, the dehumidifier process air is further cooled by passing over the sensible cooling coil (State point 3-4) where the air humidity almost remains constant but kept well below the comfort requirement. As the supply air enters the conditioned room indoor space, its temperature and humidity both maintained according to the room supply design conditions. The conditioned room air leaving the indoor room space is directed to the exhaust where it undergoes several psychrometric processes starting with cooling in an evaporative cooler (State point 5-6). This brings the air close to the saturation line with or without humidification, depending on the evaporative cooling process (direct or indirect). The air leaving the sensible cooler is then directed to the opposite in the regeneration side, first in the heat recovery wheel, so the air is preheated (State point 6-7) before it passes through the heater (State point 7-8) where its temperature is further raised so that it will be able to desorb the water from the desiccant in the regeneration side of the desiccant wheel (State point 8-9). The regeneration thermal heat source can be either an electric, solar thermal system or waste heat. A typical wheel can be spited into different process to regeneration air (R/G) ratio namely 50:50, 75:25 etc. split between dehumidification and regeneration area [20-25].

Figure 1: Solid desiccant assisted hybrid air-conditioning system (ventilation mode).

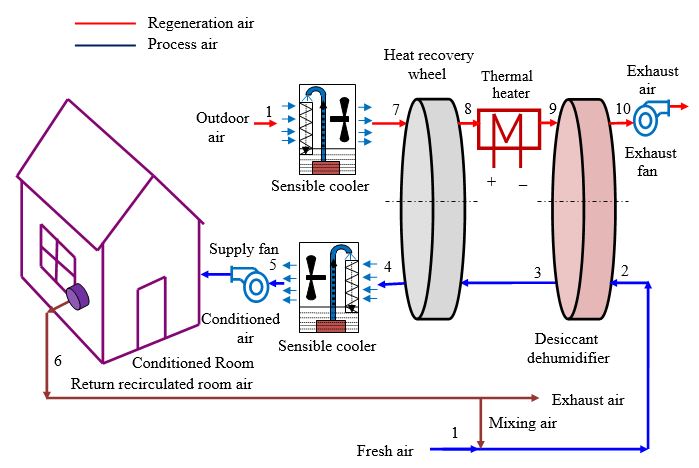

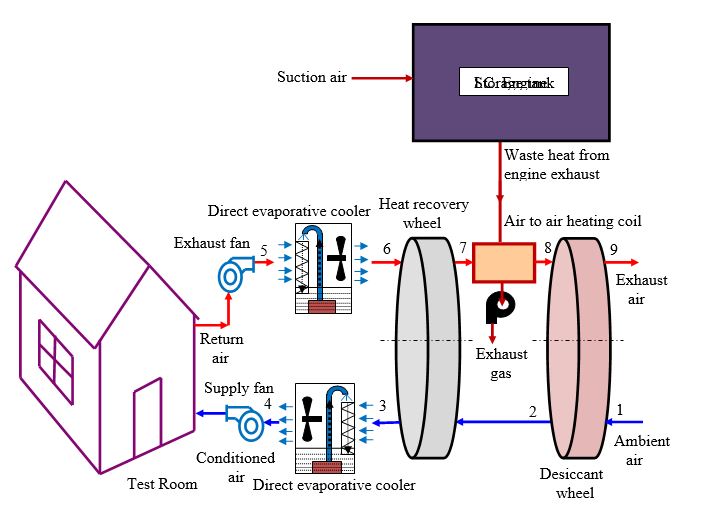

According to investigations conducted by Henning [15], this configuration is suitable for the temperate climate ambient conditions only. For a high humid climate, the dehumidification capacity of such a system is not adequate to enable the evaporative cooling system to control excess ambient air humidity. This observation is supported by a recent experimental investigations carried out for the hot and humid subtropical climate [18] where for a significantly high number of hours the resulting humidity levels fall beyond the ASHRAE upper thermal comfort boundary. Thus, although according to [6–8] such a system has a relatively high electrical and thermal coefficient of performance, the ventilation operating mode of the system may not be able to provide the required thermal comfort in the conditioned spaces [26-28]. In that case the conditioned room air is re-circulated and mixed with some proportion (5-10%) with the fresh outdoor air to maintain the oxygen level in the conditioned room as shown in Figure. 2 [29].

Figure 2: Solid desiccant assisted hybrid air-conditioning system (recirculation mode).

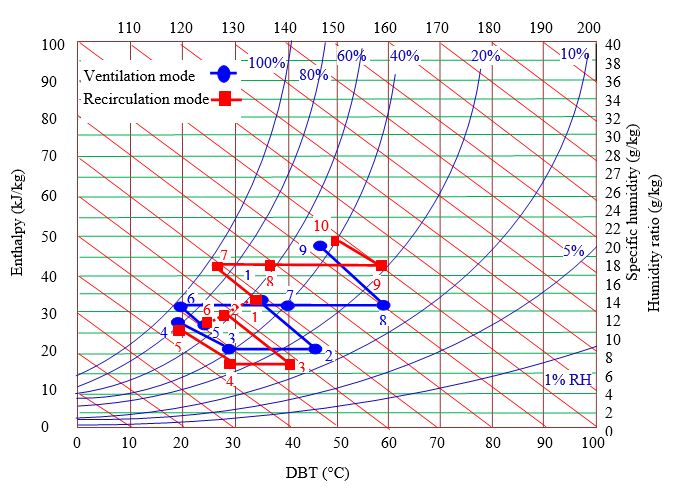

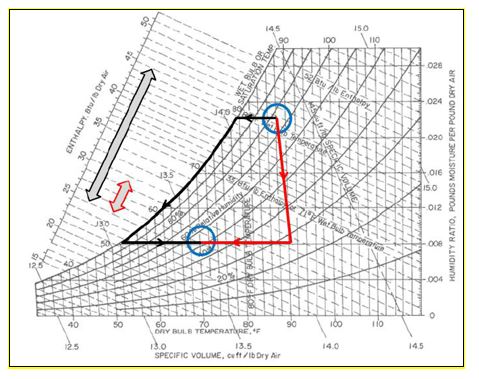

The comparison among the ventilation (blue lines) and recirculation (red lines) modes were illustrated on psychrometric chart in Figure. 3. It is seen from the graph that the recirculation operating mode saves useful energy for reactivation when ambient humidity is high. At the same time, in process side more cooling is achieved as room air re-circulated for the dehumidification can be available comparatively at lower temperature and humidity as compared to the outdoor air especially in hot and humid tropical climate [30-35]. So, that the lesser energy is required for the cooling and at the same time reactivation energy saved due to better heat exchange among both the air streams. It ultimately results to higher system performance [36-40].

Thus, it is found that the ventilation operating mode is more suitable for mile climate while the recirculation operating mode is more effective for hot and humid tropical climate. That is why optimal configuration should be adopted while using it for variable outside climatic conditions for better operational economy [41-42].

Figure 3: Comparison between ventilation and recirculation operating modes in desiccant cooling.

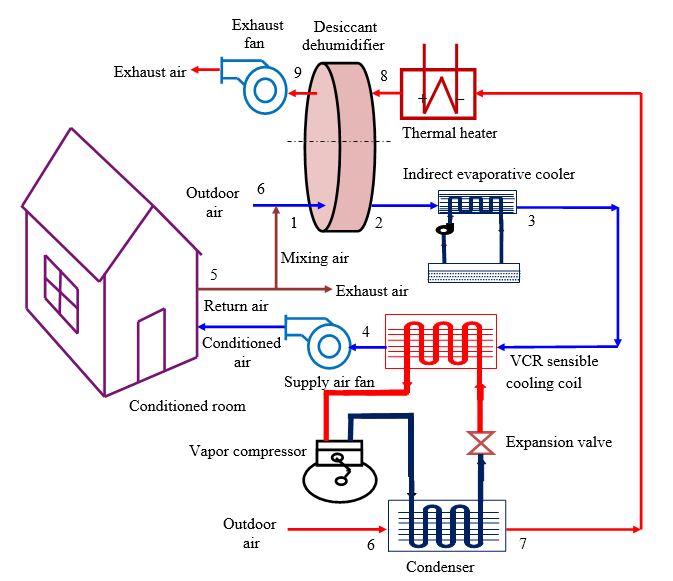

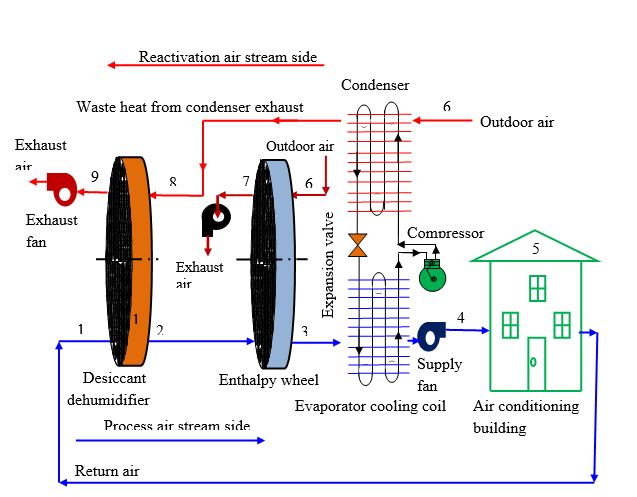

Desiccant assisted cooling system described above can effectively handle sensible heat load by passing warm and dehumidified process air over direct or indirect evaporative coolers to meet the supply design condition [43-48]. In case of hot and humid climates, these systems become inefficient due to poor dehumidification as well as cooling owing to high moisture level in the outdoor ambient. To maintain the necessary thermal comfort in the indoor space, this can be couple to the other air conditioning technologies such as traditional vapor compression air conditioning to constitute hybrid cooling system as shown in Figure. 4. This can be easily taken up the required air dehumidification and having the high sensible cooling capacity. Furthermore, to increase the efficiency of the system, condenser regeneration heat can be used for the auxiliary heating the air [49].

Figure 4: Schematic layout of solid desiccant vapor compression hybrid cooling.

The major drawback of the desiccant assisted cooling is as described above is the demand for large regeneration heat supply for desorption of the saturated desiccant during part of its rotation cycle. If this heat can be supplied from the freely available from the renewable energy source like as solar heat then the system has became economically viable. Moreover, the demand of cooling increases inline with the availability of sun radiations during the same period. The desiccant is reactivated by the thermal heat produced by renewable solar thermal energy with different types of solar collectors as shown in Figure. 5. An auxiliary heater is used when the solar radiations are insufficient to produce the required regeneration heat due to winter or cloudy seasonal conditions. Regenerating the desiccant wheel by use of solar energy is an interesting option to converge the cooling demands of space cooling as the available solar intensity is found highest during the same period [50].

Figure 5: Supply of regeneration heat by use of renewable solar energy in desiccant based hybrid cooling system.

The desiccant wheel used in the desiccant integrated hybrid cooling system can be regenerated with help of either the exhaust of internal combustion engine of large diesel generator set or industrial waste process heat as shown in Figure. 6. By this way dual advantage can be obtained first the amelioration in the dehumidification capacity of the dehumidifier used in the desiccant cooling system at the same time secondly it recovers the waste heat otherwise dissipated directly to the atmosphere as exhaust. This also reduces the operating cost of the dehumidifier. With this combination the overall efficiency of both the engine as well as cooling system both increases simultaneously. Furthermore, the efforts are still needed to develop advanced desiccant materials which are possibly got reactivated near the ambient temperature which is comparatively lower and so that it can be taken up the low temperature industrial waste heat. This also offered benefit in system COP of the desiccant assisted hybrid cooling system as compared to that of the vapor compression based traditional cooling system [51].

Figure 6: Supply of industrial waste heat for regenerating the dehumidifier used in desiccant assisted hybrid cooling system.

The desiccant used in rotary dehumidifier may also gets regenerated by use of heat recovery carried out waste heat expelled by the VCR condenser as shown in Figure. 7. This result into amelioration of cooling performance of solid desiccant based hybrid comfort space cooling system as well as efficient cooling of the condenser. Thus, reactivation heat requirement of dehumidifier used in solid desiccant based vapor compression integrated hybrid cooling can also be provided by use of VCR condenser exhaust heat otherwise it is expelled to open atmosphere [52-53]. This proves that the utilization of waste heat for dehumidifier reactivation not only achieves better energy savings but also marginal reduction in running cost of the system which results into economical feasibility of the system.

Figure 7: Use of condenser waste heat in desiccant regeneration.

Comparison of desiccant cooling with traditional cooling system

There are two conventional ways to condition the air: sensibly and latently. To cool sensibly means to reduce the dry bulb temperature (DBT) of the process air. Latent cooling refers to the removal of moisture from the conditioned air. In order to promote a healthy indoor environment, HVAC units must control the sensible and latent cooling demand of the building. Indoor air at elevated humidity levels can promote to the accumulation of bacterial growth inside the building which can be hazardous to the occupants. Oppositely, the indoor air at extremely low moisture level quickly dries the moisture from the occupant’s skin, leading to discomfort to the occupants. The key to promoting a healthy indoor environment is to supply air with enough humidity to be comfortable but low enough to avoid problems caused by excess moisture. Therefore, it is important to have efficient control over the humidity level of indoor air; especially inside buildings. The vapor compression cycle used for running the traditional HVAC units can only directly cool the sensible demand of the process air. In order to accommodate the latent cooling load, the temperature of the process air is lowered well below its dew point, allowing water vapor to be removed through condensation of conditioned air. The process of sensibly cooling below the air’s dew point results in a reduction in humidity as well as overcooling of room supply air. After the temperature of the process air is reduced, the air is then reheated to meet the temperature desired inside the conditioned space. This process is diagrammatically shown by the black colour line from the state of high temperature to low temperature in the psychrometric chart of Figure. 2. It takes substantial energy to cool humid air containing excess moisture than it does to cool dry. A desiccant assisted cooling system takes advantage of this concept by first dehumidifying the process air before it is moved into the HVAC where it is cooled sensibly. Effectively, a desiccant system lowers air conditioning energy demand by minimizing its latent cooling load. The ideal cooling of process air by a desiccant powered dehumidification and air conditioning unit is depicted by the red colour line in the psychrometric chart of Figure. 8. The dehumidification process of the desiccant cooling is represented by the nearly vertical section of the red colour line. As the air is dehumidified, it rises in temperature slightly before being moved into the conditioning unit. After dehumidification, the process air is cooled sensibly by the traditional cooler to meet the demand of desired temperature of the conditioned space. It is necessary to control the humidity of air as recirculated air at extremely low relative humidity quickly dries the moisture from the occupant’s skin, leading to discomfort. The key to ameliorate a healthy indoor environment is to supply air with enough humidity to be comfortable but low enough to avoid problems caused by moisture. Therefore, it is important to have efficient control over the humidity level of indoor air; especially inside a home [58-61].

Figure 8: Comparison between VCR cooling (black line) and desiccant cooling (red line) on psychrometric chart.

The comparison between conventional cooling and desiccant cooling can be elaborated in following table 1.

|

Table 1: Comparison between vapor compression based traditional cooling and desiccant cooling. |

||

|

Parameters |

Conventional cooling |

Desiccant cooling |

|

Operating cost |

High |

Saves 41-48% |

|

Indoor air quality |

Average |

High |

|

Effect on environment |

Harmful |

Eco-friendly |

|

Energy source |

Electricity |

Low grade heat like waste heat or renewable solar energy |

|

Moisture removal capacity |

Average |

High |

Advantages of desiccant cooling as compared to the traditional air-conditioners can be summarized as follows:

1. Desiccant cooling systems can be operated by use of low-grade thermal energy sources like solar energy.

2. Desiccant cooling system is environmentally friendly as it does not use CFC based refrigerants which are responsible for global warming.

3. Over cooling and reheating of conditioned air supply can be avoided by use of desiccant desorption to control the humidity in air.

4. Leakage is avoided as desiccant cooling system operated nearly at ambient pressure.

5. Less prone to corrosion and wetting the supply duct.

A desiccant cooling system consists of passing humid (and warm) air through a desiccant laden dehumidifier rotary wheel for drying and through a cooler for sensible cooling to provide conditioned air. The desiccant material used in the rotary dehumidifier becomes saturated with water and needs to be regenerated with hot air provided by an energy source (e.g., sun, natural gas, waste heat, or electricity). The cost, efficiency, and durability of a desiccant cooling/dehumidification system depend on those of the components used in the system.

Conclusions

The present study summarizes use of desiccant dehumidification system in modern air conditioning in energy saving and green cooling approach in building comfort cooling. Desiccant based hybrid cooling systems can achieve substantial energy savings by use of freely available solar energy or waste heat from industrial processes for reactivation of desiccant material used in rotary dehumidifiers used in the system to make the hybrid cooling system more cost effective. It can also help to alleviate the peak supply of electrical power demanded by the conventional vapor compression air conditioning system required during the hot sunny days by use of renewable solar energy. Future innovations in the type of desiccant materials which get regenerated at lower reactivation temperature by making use of available low temperature waste will augmenting the contribution of desiccant cooling which can bring to the amelioration of comfort, energy and cost savings. Further improvement in energy utilization rate, reduction in cost and size, competitive design and production are the key factors to be faced by desiccant assisted modern air conditioning techniques for obtaining more extensive acceptability in the field of space cooling.

Nomenclature

COP Coefficient of performance

RH Relative humidity (%)

R/P Regeneration air flow/process air flow

T Dry bulb temperature (°C)

V Flow rate of air stream (m3/hr)

VCR Vapor compression refrigeration

Subscripts

0 Dead state

1,2, etc. State numbers

CC Cooling coil

EC Evaporative cooler

DW Desiccant wheel

h heat source

HRW Heat recovery wheel

p Process air

r Regeneration air

References

1. Goldworthy M, White S. 2011. Optimisation of a desiccant cooling system design with indirect evaporative cooler. Int. J. Refrig. 34: 148-158. Ref.: https://bit.ly/33n1CII

2. Narayanan R, Saman WY, White S. 2011. Comparative study of different desiccant wheel designs. Appl. Therm. 31: 1613-1620. Ref.: https://bit.ly/33mu8uf

3. Narayanan, R. 2012. Development of a Thermally-Driven Solid Desiccant System for Dehumidification/Cooling. Ph.D. Thesis, University of South Australia, Adeliade, Australia.

4. Narayanan R, Saman WY, White S. 2013. A non-adiabatic desiccant wheel: Modeling and experimental validation. Appl. Therm. 61: 178-185. Ref.: https://bit.ly/2Om1DbS

5. Dezfouli MMS, Mat S, Pirasteh G, et al. 2014. Simulation Analysis of the Four Configurations of Solar Desiccant Cooling System Using Evaporative Cooling in Tropical Weather in Malaysia. Int. J. Photo energy. 14: 1-14. Ref.: https://bit.ly/2OIYody

6. Ma Y, Guan L. 2015. Performance analysis of solar desiccant-evaporative cooling for a commercial building under different Australian climates. Procedia. 121: 528-535. Ref.: https://bit.ly/2KVqroW

7. Ma Y, Guan L, Brown R. 2015. Techno-economic Analysis of a Solar Desiccant-Evaporative Cooling System with Different Collector Types for Australian Office Buildings. In Proceedings of the 2015 Asia–Pacific Solar Research Conference, Brisbane, Australia. Ref.: https://bit.ly/34nLZ55

8. Ma Y, Saha SC, Miller W, et al. 2017. Comparison of Different Solar-Assisted Air Conditioning Systems for Australian Office Building. 10: 1463-1473. Ref.: https://bit.ly/33jRP6p

9. Narayanan R. 2019. Solid-and gas-side resistances in a desiccant wheel. Energy Procedia. 160: 139-146. Ref.: https://bit.ly/2DjPnSU

10. Keleher M, Narayanan R. 2019. Comparative study of alternative HVAC systems incorporating renewable energies in sub-tropical climates. Energy Procedia. 160: 147-154. Ref.: https://bit.ly/2QPLvRl

11. Pesaran AA, Mills AF. 1987. Moisture transport in silica gel packed beds_I. Theoretical study. Int. J. Heat Mass Transf. 30: 1037-1049. Ref.: https://bit.ly/2XM54M1

12. Pesaran AA, Penny R, Czanderna AW, 1992. Desiccant Cooling: State-of-the-Art Assessment. National Renewable Energy Lab. Golden, CO, USA. Ref.: https://bit.ly/2rnDecW

13. Narayanan R, 2017. Investigation of geometry effects of channels of a silica-gel desiccant wheel. Energy Procedia. 110: 20-25. Ref.: https://bit.ly/2Okwcyl

14. Narayanan R. 2015. Theoretical modelling of silica gel desiccant wheels. Appl. Mech. Mater. 787: 311-317. Ref.: https://bit.ly/2Dglzq7

15. Henning HM. 2007. Solar assisted air conditioning of buildings–an overview. Appl. Therm. 27: 1734-1749. Ref.: https://bit.ly/2OmeRoN

16. Camargo JR, Ebinuma CD. 2005. An evaporative and desiccant cooling system for air conditioning in humid climates. J. Braz. Soc. 27: 243-247. Ref.: https://bit.ly/2OlDxOj

17. Jain, S, Dhar PL. 1995. Evaluation of solid-desiccant-based evaporative cooling cycles for typical hot and humid climates. Int. J. Ref. 18: 287-296. Ref.: https://bit.ly/2OOtTmx

18. Narayanan R, Halawa E, Jain S. 2018. Performance Characteristics of Solid Desiccant Evaporative Cooling Systems in Australian Climate Zone of Brisbane. 11: 2574. Ref.: https://bit.ly/2QTbYxI

19. Jani DB, Mishra M, Sahoo PK. 2016. Solid desiccant air conditioning- A state of the art review. Renew Sustain Energy Rev. 60: 1451-1469. Ref.: https://bit.ly/2qLtvgr

20. Jani, DB, Mishra M, Sahoo PK. 2018. A critical review on solid desiccant based hybrid cooling systems. Int J Air-condition Refri. 25: 1-10. Ref.: https://bit.ly/33jWC7T

21. Jani, DB, Mishra M, Sahoo PK. 2015. Performance studies of hybrid solid desiccant - vapor compression air-conditioning system for hot and humid climates. Energy and Buildings. 102: 284-292. Ref.: https://bit.ly/33qMjPz

22. Pandelidisa D, Pacaka A, Cichon A, et al. 2018. Multi-stage desiccant cooling system for moderate climate. Energy Convers. Manag. 177: 77-90. Ref.: https://bit.ly/2Oj9WoL

23. Kanoglu M, Carpinlioglu MO, Yildirim M. 2004. Energy and exergy analysis of an experimental open-cycle desiccant cooling system. Appl. Therm. 24: 919-993. Ref.: https://bit.ly/34mP9pU

24. Jani, DB, Mishra M, Sahoo PK. 2016. Performance prediction of rotary solid desiccant dehumidifier in hybrid air-conditioning system using artificial neural network. Applied Thermal Engineering. 98: 1091-1103. Ref.: https://bit.ly/37GvC5G

25. Bejan A, Tsatsaronis G, Moran M. 1966. Thermal Design and Optimization. John Wiley & Sons, New York, U.S.A., Chap. 3: 113-163. Ref.: https://bit.ly/37Eh2fa

26. Jani, DB, Mishra M, Sahoo PK. 2016. Performance analysis of hybrid solid desiccant – vapor compression air-conditioning system in hot and humid weather of India. Building Services Engineering Research and Technology .37: 523-538. Ref.: https://bit.ly/33mR8ct

27. Van den Bulck E, Mitchell JW, Klein SA. 1986. The use of dehumidifiers in desiccant cooling and dehumidification systems. Transactions of ASME .108: 684-691. Ref.: https://bit.ly/2XRIrG6

28. Jani, DB, Mishra M, Sahoo PK. 2016. Performance prediction of solid desiccant - vapor compression hybrid air-conditioning system using artificial neural network.103: 618-629. Ref.: https://bit.ly/2OkWxMP

29. Daou K, Wang RZ, Xia ZZ. 2006. Desiccant cooling air conditioning: a review. Renew Sustain Energy Rev. 10: 55-77. Ref.: https://bit.ly/2KRn6Hm

30. Jani, DB, Mishra M, Sahoo PK. 2016. Experimental investigation on solid desiccant – vapor compression hybrid air- conditioning system in hot and humid weather. Applied Thermal Engineering. 104: 556-564. Ref.: https://bit.ly/35ByX4o

31. Liu XH, Zhang T, Zheng TW, et al. 2016. Performance investigation and exergy analysis of two-stage desiccant wheel systems. Renewable Energy. 86: 877-888. Ref.: https://bit.ly/2XNt6pJ

32. Jani, DB, Mishra M, Sahoo PK. 2016. Exergy analysis of solid desiccant - vapor compression hybrid air conditioning system. International Journal of Exergy .20: 517-535. Ref.: https://bit.ly/2KUA0US

33. White SD, Kohlenbach P, Bongs C. 2009. Indoor temperature variations resulting from solar desiccant cooling in a building without thermal backup. Int. J. Refrig. 32: 695-704. Ref.: https://bit.ly/35y0rru

34. Jani, DB, Mishra M, Sahoo PK. 2017. Application of artificial neural network for predicting performance of solid desiccant cooling systems- A review. Renewable and Sustainable Energy Reviews. 80: 352-366. Ref.: https://bit.ly/2DtQWxL

35. Worek WM, Moon CJ. 1986. Simulation of an integrated hybrid desiccant vapor-compression cooling system.11: 1005-1021. Ref.: https://bit.ly/2KVJNtW

36. Jani DB, Shah N, Panchal N. 2018. A review on application of desiccant dehumidification - vapor compression hybrid cooling system in hot-humid climates. Int J Inno Emerg Res Eng. 5: 1-5.

37. Hwang WB, Choi S, Lee DY. 2017. In-depth analysis of the performance of hybrid desiccant cooling system incorporated with an electric heat pump. 118: 324-332. Ref.: https://bit.ly/37EmrTu https://bit.ly/37EmrTu

38. Jani DB, Lalkiya D, Patel S. 2018. A critical review on evaporative desiccant cooling. Int J Inno Emerg Res Eng. 5: 24-29.

39. Beccali M, Finocchiaro P, Nocke B. 2012. Energy performance evaluation of a demo solar desiccant cooling system with heat recovery for the regeneration of the adsorption material. Renew. Energy. 44: 40-52. Ref.: https://bit.ly/2Di9l0f

40. Jani DB, Mishra M, Sahoo PK. 2018. A critical review on application of solar energy as renewable regeneration heat source in solid desiccant – vapor compression hybrid cooling system. Journal of Building Engineering. 18:107-124. Ref.: https://bit.ly/2KPVsKX

41. Merabti L, Merzouk M, Merzouk NK, et al. 2017. Performance study of solar driven solid desiccant cooling system under Algerian coastal climate. Int. J. Hydrogen Energy. 42: 28997-29005. Ref.: https://bit.ly/2KUmnoY

42. Jani, DB, Mishra M, Sahoo PK. 2018. Performance analysis of a solid desiccant assisted hybrid space cooling system using TRNSYS. Journal of Building Engineering .19: 26-35. Ref.: https://bit.ly/35BEsQA

43. Fong KF, Chow TT, Lee CK, et al. 2010. Advancement of solar desiccant cooling system for building use in subtropical Hong Kong. Energy Build. 42: 2386-2399. Ref.: https://bit.ly/2pT5ZxJ

44. Jani, DB, Mishra M, Sahoo PK. 2018. Investigations on effect of operational conditions on performance of solid desiccant based hybrid cooling system in hot and humid climate. Thermal Science and Engineering Progress. 7: 76-86. Ref.: https://bit.ly/2QRSV6Q

45. Rambhad KS, Walke PV, Tidke DJ. 2016. Solid desiccant dehumidification and regeneration methods: A review. Renew. Sustain. Energy Rev. 59: 73-83. Ref.: https://bit.ly/37AED0p

46. Jani DB. 2019. Liquid desiccants application in cooling and dehumidification – An overview. Archives of Industrial Engineering. 2: 1-17.

47. Jani DB, Bhabhor KK, Dadi M. et al. 2019. A review on use of TRNSYS as simulation tool in performance prediction of desiccant cooling cycle. Journal of Thermal Analysis and Calorimetry. 1-21. https://bit.ly/2qNDq51

48. Bhabhor KK, Jani DB. 2019. Progressive development in solid desiccant cooling: A review. International Journal of Ambient Energy. Ref.: https://bit.ly/2XNH0YW

49. Jani DB. 2019. An overview on recent development in desiccant materials. International Journal of Advanced Materials Research. 5: 31-37.

50. Jani DB. 2019. Progressive review on use of desiccant drying in agricultural applications. Journal of Agricultural Science and Engineering .5: 24-31.

51. Joshi A, Jani DB. 2018. A review on desiccant based cooling and dehumidification systems. Int J Inn. Knowledge Con. 6: 218-221.

52. Patanwar P, Shukla SK. 2014. Mathematical modelling and experimental investigation of the hybrid desiccant cooling system. Int J Sustain Energy. 33: 103-111. Ref.: https://bit.ly/2DgzXyu

53. Narayanan R, Halawa E, Jain S. 2018. Performance characteristic of solid-desiccant evaporative cooling system. 11: 25-74. Ref.: https://bit.ly/2Ok3Fcg

54. Bareschino P, Pepe F, Roselli C, et al. 2019. Desiccant-Based Air Handling Unit Alternatively Equipped with Three Hygroscopic Materials and Driven by Solar Energy. 12: 1543-1557. Ref.: https://bit.ly/2Demrf1

55. Li H, Dai YJ, Li Y, et al. 2012. Case study of a two-stage rotary desiccant cooling/heating system driven by evacuated glass tube solar air collectors. Energy Build. 47: 107-112. Ref.: https://bit.ly/2XMuGs9

56. Speerforck, A, Ling J, Aute V, et al. 2017. Modeling and simulation of a desiccant assisted solar and geothermal air conditioning system. 141: 2321-2336. Ref.: https://bit.ly/2rrwElw

57. Pandelidis D, Pacak A, Cichon A, et al. 2018. Multi-stage desiccant cooling system for moderate climate. Energy Converse Manage. 177: 77-90. Ref.: https://bit.ly/2qCQNVW

58. Comino F, de Adana MR, Peci F. 2018. Energy saving potential of a hybrid HVAC system with a desiccant wheel activated at low temperatures and an indirect evaporative cooler in handling air in buildings with high latent loads. Appl Therm Eng. 131: 412–427. Ref.: https://bit.ly/2XTqOFJ

59. Tu R, Hwang Y. 2018. Efficient configurations for desiccant wheel cooling systems using different heat sources for regeneration. Int J Refrig. 86: 14-27. Ref.: https://bit.ly/37Ec7Lm

60. Fong KF, Lee CK. 2018. New perspectives in solid desiccant cooling for hot and humid regions. Energy Build. 158: 1152-1160. Ref.: https://bit.ly/2XMlvaY

61. Heidari A, Roshadel R, Vakiloroaya V. 2019. An innovative solar assisted desiccant based evaporative cooling system for co-production of water and cooling in hot and humid climates. Energy Converse Manage .2019: 396-409. Ref.: https://bit.ly/37EFsoR