Indexing & Abstracting

Full Text

Review ArticleDOI Number : 10.36811/ojrmi.2022.110045Article Views : 0Article Downloads : 1

Engineering and Designs Mistakes in Radiology

Abdulwahab Alahmari*

Radiology Specialist, Radiology Department, Al-Namas General Hospital, Ministry of Health, Al- Namas City, Saudi Arabia

*Corresponding Author: Abdulwahab Alahmari, Radiology Specialist, Radiology Department, Al- Namas General Hospital, Ministry of Health, Al-Namas City, Saudi Arabia, Tel: +966562428716; Email: afaa99@hotmail.co.uk

Article Information

Aritcle Type: Review Article

Citation: Abdulwahab Alahmari. 2022. Engineering and Designs Mistakes in Radiology. O J Radio Med Img. 5: 13-17.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2022; Abdulwahab Alahmari

Publication history:

Received date: 09 May, 2022Accepted date: 25 May, 2022

Published date: 27 May, 2022

Abstract

Biomedical engineers make many mistakes in designing radiology machines and these mistakes stay there for the lifespan of the machine. The reason why they make these mistakes is that they do not use the machine on daily bases and scan patients with it every day. Many inventions in the medical field are not made by engineers, but medical health professionals. Many unsolved problems still do exist because simply engineers and manufacturing companies of the radiology machines do not see them. Another cause is the financial benefits where manufacturing companies focus on selling their products, not well designing them first. The aim of this paper is to show some of these wrong designs and propose ideas for solving the issues.

Keywords: Radiology; Designs; Mistakes; Engineering; Manufacturing

Examples of the Deigns Mistakes

Design issue number 1: Siemens -in my personal opinion- is the best manufacturing company for CT scanners. But with an examiner eye and professional experience as a CT scan Radiographer, there are some poor designs can be spotted. For example, there is a hanger used to hold the blue sheet that covers the patient table. The sheet is important especially in infection prevention. The hanger is located below the table of the CT scanner for no reason. After cutting the used part of the blue sheet, the sheet will fall on the floor of the CT room. The radiographer hasto cut the blue sheet every time, because it lies down on the floor for hygienic reasons and the patients would not want used it if they see it on the floor. It falls down on the floor because the air-conditioning system in the room because the CT scanners depends on air cold system to cool the machine down and a proposal have been made recently to fix related issues with the cold CT scanner rooms [1]. The water cold system is even worse than the air-cold system [1]. The cooling systems until today is another dilemma that engineers did not solve it yet! The easy solution for the blue sheet issue for holding the blue sheet is to put a holder above the couch to hold the blue sheet at the end of the couch (i.e., feet side) see (Figures. 1 and 2). When place the blue sheet roll in top of the bed and try to spread it, it falls down and someone required to hold the blue sheet roll and one spread the sheet to the other end of the table. A simple holder above the table can make it easier!

Figure 1: The design issue. The blue sheet on the machine hanger to hold it, but it falls on the ground.

Figure 2: The solution. This is the best location for the blue sheet, but it needs something to hold the sheet in one place to allow spreading the sheet easily. The holder needs to be manufactured by the company.

Design issue number 2: For example, the biggest mistake ever made in radiology is the RIS system made by Carestream. The system is not good to be used anywhere and especially in radiology. The system for example required too many information to fill that has no importance like the religion of the patient. The patient will wait forever until the reception staff finish the patient request and sent to the system. Instead of making a simple system that needs four things; name, ID number, gender, and age and to accept the study in two clicks, they made a system that will take forever to look for the patient study, then confirm the study, then accept the study, then schedule the study, then make the patient arrive on the system, then make the patient start the test in the system! The system wastes the Radiographer’s time and the patient’s time. There are other issues reported before [2].

Design issue number 3: Metal artifact reduction (MAR) algorithms are another example of failure of biomedical engineering in making new algorithms because these MAR algorithms introduced new artifacts [3]. I partially solved this issue by using the bone window which reduced the streak artifacts and allows anyone to see the broken bones and hemorrhage in the sinuses as in this gun shoot case. The image quality still has less streak artifacts, but the artifacts still seen in the CT images see (Fig 3).

Figure 3: The design issue and the solution in one image. Streak artifact from a bullet in a patient. Applying bone window will cut most of the streak artifact. The image (A) with streak artifact blocking all information. The image (B) with bone window which allowed seeing the fractures in the bones, the hemorrhage, and the location of the bullet.

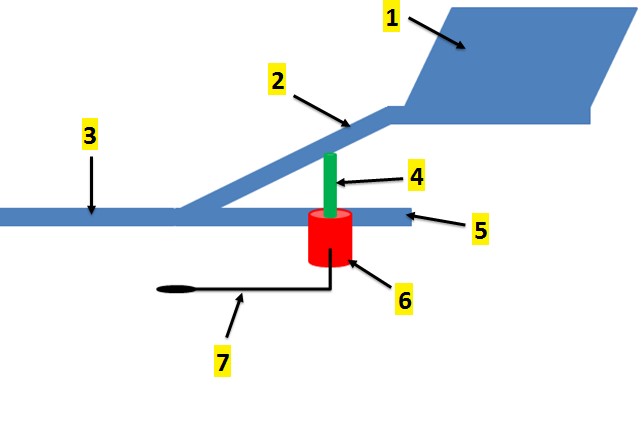

Design issue number 4: Some patient has stiff neck due to their life style or some pathological process in the spine which cause stiff neck. When they lie down, their heads do not touch the head holder and the brain will be out of the field of the imaging. There will be literally cut in the brain picture if they do not lie down properly. The issue is that they can’t. As a radiographer I would ask a family member to wear lead apron and hold the patient neck back. The best solution is to bring the neck supporter near the patient neck. The head holder will have a gas cylinder like any office chair and lever to push the neck supporter near the patient neck. The proposed design is seen in (Figures. 4 and 5). As well, I proposed previously in another paper that was published recently a head holder that can help in such cases [4]. The field of view of CT scanner must be increase in such cases by using chest or abdomen protocol imaging with the head to increase the field of view then manipulate the viewing window to brain window. The entire head holder must be made of non-metallic parts and use only carbon fiber as much as they can.

Figure 4: The solution 1) CT scan head holder, 2) neck supporter, 3) the part attached with the patient table, 4) rod, 5) the gas cylinder holder, 6) the gas cylinder, and 7) lever.

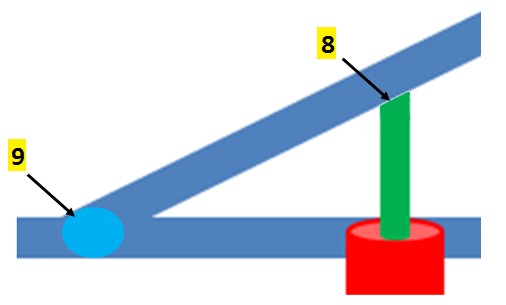

Figure 5: The solution. 7) beveled tip of the rod, and 9) joint connects the gas cylinder holder (the fixed part) and the neck supporter part (the movable part).

Other design issues

Recently Abdulwahab Alahmari published two papers one is about a head holder used to hold patients with severe tremors, so radiographers will be able to do a CT scan for the brain [4]. The other paper is about using a table warmer to help the patients feel warm in the cold CT rooms where they used air-cooled CT systems [1].

Conclusion

Medical health professionals and especially Radiographer must be more involved with the manufacturing companies in the designing of the CT scanners. Engineers do not understand what is required for the patients, so the scan can be conducted easily. Engineering companies must fix their machines and go and speak with Radiographers to get some feedback about their products.

References

1. Abdulwahab Alahmari. 2022. Cold CT scanner rooms: A simple solution for the patient comfort and for hypothermia cases. O J Radio Med Img. 5: 07-09.

2. Alahmari A. 2020. National or regional PACS and RIS: Editorial. J Clin Res Radiol. 3: 1-2.

3. Bolstad K, Flatabø S, Aadnevik D, et al. 2018. Metal artifact reduction in CT, a phantom study: subjective and objective evaluation of four commercial metal artifact reduction algorithms when used on three different orthopedic metal implants. (2018) Acta radiologica. (Stockholm, Sweden: 1987). 59: 9.

4. Alahmari A. 2022. A Proposal of a Head Holder for CT Scan Tables: A New Fixation Design. Austin J Radiol. 9: 1191.